When a vehicle is turned into a mobile work unit, whether that is an ambulance, welfare vehicle or utility vehicle, the work done to ensure it is operational is neatly hidden away.

This year we have worked with our customer Blue Light Service to fit out Renault Master High Dependency Unit Ambulances.

These are different to Front-Line A&E vehicles, as they are designed to transport critical and non-critical patients that require movement between hospitals and GP Surgeries.

Nevertheless they still require their own power management and switch control functions.

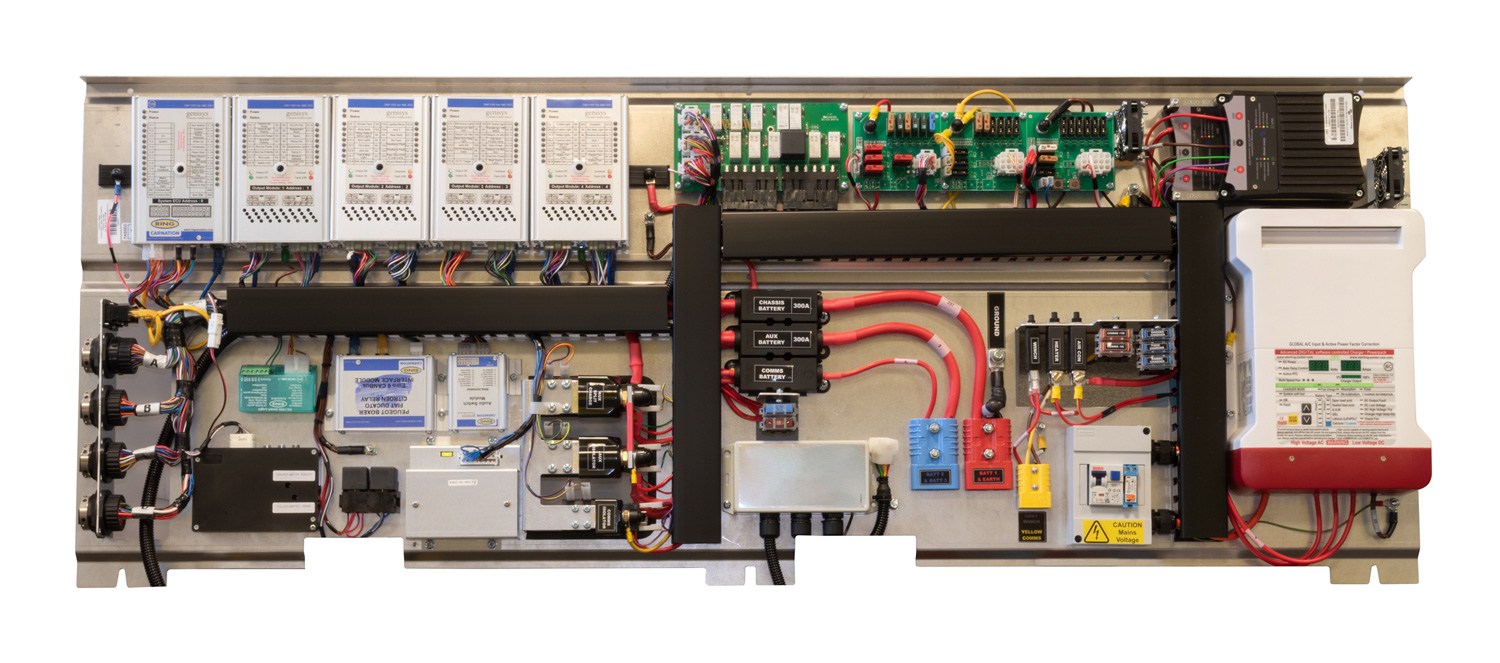

Our Ring Carnation engineers produced a bespoke backboard for 65 vehicles, using the genisys™ system. This reduces wiring, and installation times, but being software driven can be updated in the future aiding the full life of vehicles use.

The complete configuration included :

- Keypad & Touchscreen Assembly.

- Backboard full system build with genisys™ modules.

- Ring RSCDC1250 DC-DC charger and an RINVPAR10 inverter for additional power support.

- Full and final system test before installation.

While we are delighted to see them leave our factory, we know, once installed, no one will get to see the great work done to make sure these vehicles remain operational. So we wanted to share the planning and detail of our backboards and how wiring is kept to a minimum.

Creating bespoke backboards for various specialist vehicles is what makes our proposition unique.

We take away the hassle of configuring all the wiring and extra functions and wrap it up in one neat tailored solution that can be fitted easily and quickly.

No matter how complex the demands or requirements, our engineers work with customers to create purpose-built power management back boards.

For comparison, a front line ambulance backboard looks like this: